Introduction

Company Introduction

TMD Lab is an R&D-oriented

company with original technology related to shape memory polymers.

We have established a medical device pipeline with excellent controllability and a wide spectrum of physical properties and expandedour business to multi-D printing, textile chemistry industry, and material parts industries. As such, we are presenting new solutions in various industries.

The founder, Professor Hak-joon Sung, first developed theoriginal material technologyfor the shapememory polymer based on polycaprolactone while working for Vanderbilt University in the United States.

After joining asa professor at Yonsei University in Korea in 2018, Professor Hak-joon Sung further developed the source material technology of the shape memory polymer and started research on convergence medicinesand the development of the technology for medical devices that can be inserted into the body.

Since its foundation, TMD Lab has continued to develop the source material technologyfor five generations of the shape memory polymer by utilizing not only polycaprolactone but also various biocompatible polymers.

Currently, mass synthesis is enabled, and various production process techniques such as Multi-D printing, molding, and injection have been developed using the mass synthesis technology, and we are expanding the pipeline into various industries.

CEO’s Introduction

We strive to globalize the original technology of K-Medical materials.

Received the top 3 U.S. Scientist Award and Korea Pfizer Medical Award.

Published more than 20 papers in sister journals of Nature Science in the last 3 years.

Received more than 20 billion won for research projects.

- - Currently, Head Professor at Yonsei University Medical School

- - Doctor of Engineering, Georgia Tech & Emory University, USA

- - Adjunct Professor at the Department of Mechanical Engineering, Georgia Tech, USA

- - Adjunct Professor at the Biotechnology Research Centerof Pohang University of Science and Technology

- - Chairman of the Medical Engineering Subcommittee in Vascular Research Group of the KoreanSociety of Cardiology

- - Expert in technology level evaluation in the life, health and medical fields of the Ministry of Science and ICT

- - Chairman of the Advanced Regenerative Medicine and Advanced Biopharmaceuticals Review Committee Convergence Treatment Specialist Committeeunder the Ministry of Health and Welfare

- - Former Professor at Vanderbilt University

- - Publication of 165 SCI(E) papers

- - Registration of 5 US patents, 5 PCTs, and1 EP

- - Registration of 2 domestic patents and application of 17 domestic patents

- - 7 technology transfers

History

Foundation Building Stage

- Professor Hak-joonSung’s research team at Vanderbilt University in the U.S. completed the development of the source technology for the ‘1st generation’ and ‘2nd generation’ of shape memory polymers

- Invested over 10 billion won in research

Growth Stage

- Completed the development of the source technology for the 3rd generation of shape memory polymer

- Developed a prototype of implantable medical devices using shape memory polymers

Establishment and Building Stage

- Established thecorporation and secured investment

- Secured multiple pipelines

- Preparedfor licensing of shape memory polymer-based implantable medical devices

- Expandedthe source material technology for TMD Lab's unique shape memory polymer

- Developed convergence medicines using shape memory polymers

Leap Stage

- Acquired venture business certification and manufacturing license

- Attracted Series A investment in 2020 (KRW 5.77 billion)

- Expanded and relocatedthe headquar ters, research institute, and factory

- Selected as ‘Strategic Startup Project’ (TIPA) and awarded R&D fund of 400 million

- Acquireda certificate for medical device manufacturing and quality control standard conformity (GMP, No. 6742)

- Acquired INNO-BIZ certification (No. 210105-01855)

- Attracted Series B investment in 2021-22 (KRW 10 billion)

- Selected as ‘Strategic Startup Growth Technology Development Project’ and awarded R&D fund of 300 million.

Vision

Business Model

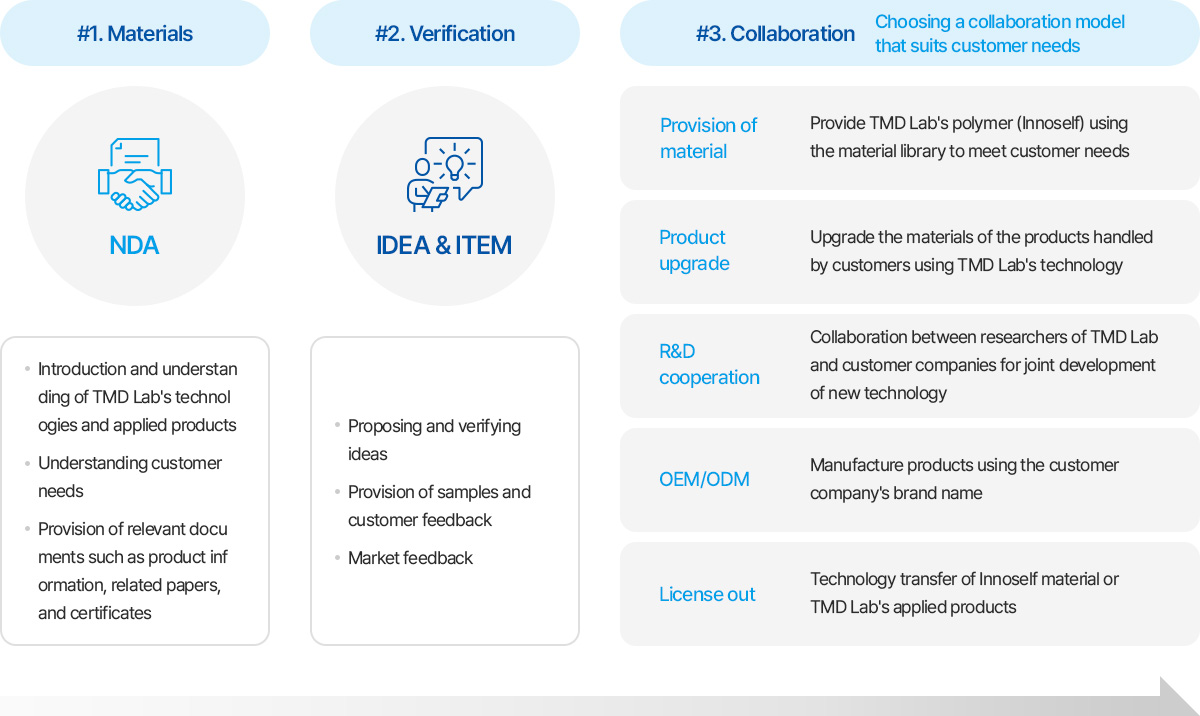

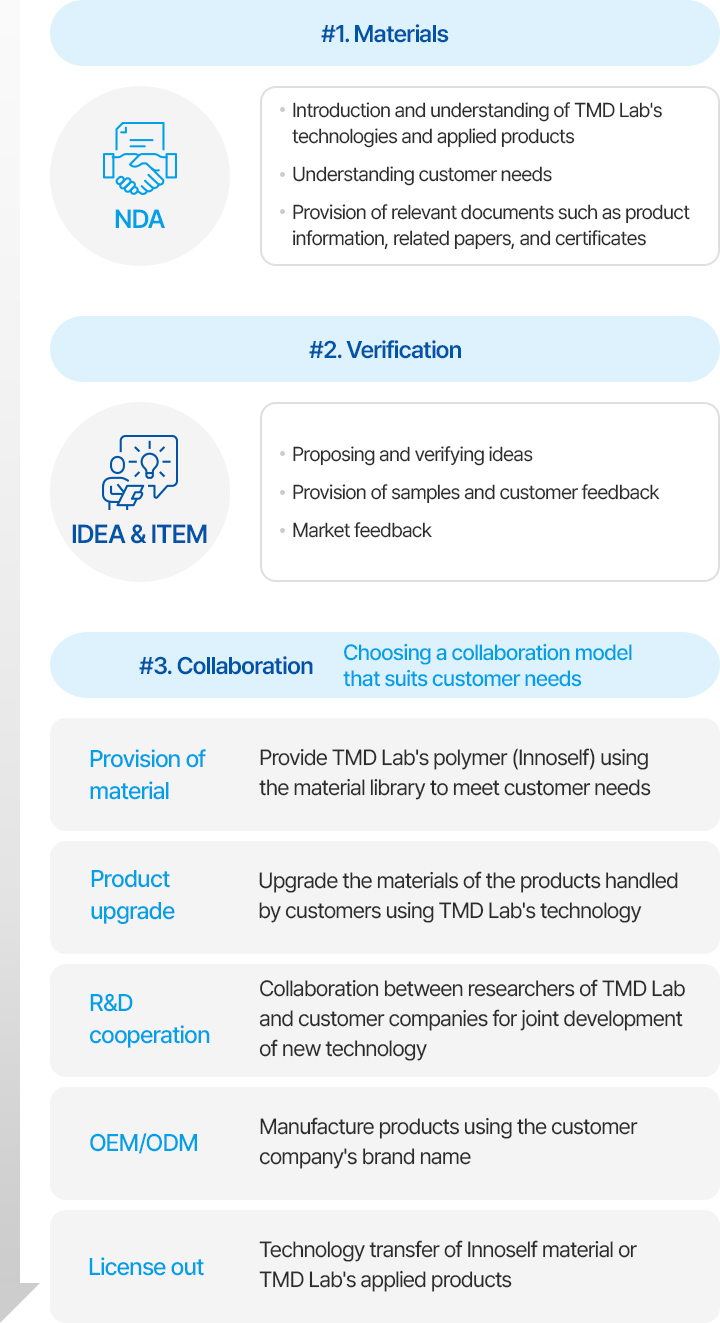

Collaboration Progress Stages

R&D cooperation stage

-

01

Identifying customer needs

-

02

Proposal of the application method and discussion on the verific ation method

-

03

1st verification

-

04

Signing MOU

-

05

Consultation on R&D contract conditions

-

06

Conclusion and execution of the contract

Material/product provision stage

-

01

Introduction of products/materials

-

02

Market research and provision of sample (1st verification)

-

03

Signing MOU

-

04

Market evaluation

-

05

Negotiation of supply contract conditions

-

06

Conclusion and execution of the contract