News

TMD Lab - Yonsei University College of Medicine Joint Research, selected as a “medical device customized material” national assignment. (Sep 15, 2020)

TMD LAB

2023-01-05

Number of views 2,366

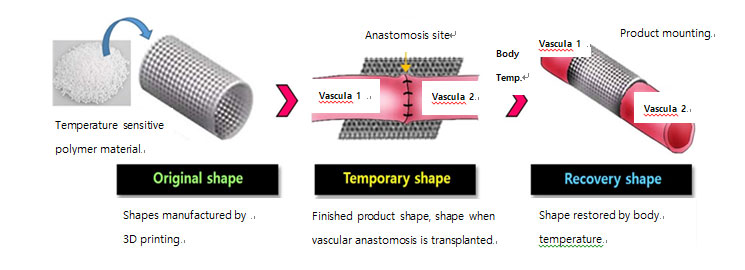

The research selected as a National assignment this time is to develop a “temperature-sensitive medical device for assisting vascular anastomosis,” to improve the success rate of surgical transplantation. Through this project, it is expected to develop and commercialize a human implantable polymer medical device that prevents stenosis inside blood vessels during surgical operations such as organ transplant surgery and breast reconstruction surgery. It will receive 2.5 billion won from the government out of the 3 billion won project cost for all four years.

The research team of Professor Hak-Joon Sung of Yonsei University College of Medicine, which is the leading research institute, and a team of Severance surgeons will conduct preclinical tests and evaluation of the biological safety, physical properties, and physicochemical performance of the prototype, and TMD Lab will manage development and construction of a mass synthesis system for polymers. Professor Hak-Joon Sung of Yonsei University, a registered director of TMD Lab, has been a professor at Georgia Tech and Vanderbilt University, and is considered an expert in the field of polymer research.

Mi-ran Kang, CEO of TMD Lab points out that, “There are currently no similar products for medical devices related to stenosis of vascular anastomosis and vessel regeneration.” It can be applied to various human implantable medical device markets such as stents, artificial fabrics, and needle-type patches.”

Carima, a leading 3D printing company (CEO Lee Byung-keuk), will also study the manufacturing technology of 3D printing-based body temperature-sensitive polymers as a participating organization.

The research team of Professor Hak-Joon Sung of Yonsei University College of Medicine, which is the leading research institute, and a team of Severance surgeons will conduct preclinical tests and evaluation of the biological safety, physical properties, and physicochemical performance of the prototype, and TMD Lab will manage development and construction of a mass synthesis system for polymers. Professor Hak-Joon Sung of Yonsei University, a registered director of TMD Lab, has been a professor at Georgia Tech and Vanderbilt University, and is considered an expert in the field of polymer research.

Mi-ran Kang, CEO of TMD Lab points out that, “There are currently no similar products for medical devices related to stenosis of vascular anastomosis and vessel regeneration.” It can be applied to various human implantable medical device markets such as stents, artificial fabrics, and needle-type patches.”

Carima, a leading 3D printing company (CEO Lee Byung-keuk), will also study the manufacturing technology of 3D printing-based body temperature-sensitive polymers as a participating organization.

[The principle action of a prototype product for prevention of vascular anastomosis stenosis and regeneration of vessels]

After being inserted into the human body, a polymer material is restored in a form that wraps the outer wall of blood vessels at body temperature.

After being inserted into the human body, a polymer material is restored in a form that wraps the outer wall of blood vessels at body temperature.